Mother of pearl tiles also can called as mother of pearl panel,shell tiles or shell tiles. Because those mother of pearl

tiles are made by 100% natural shell and its own finished loose shell chips thickness only have 2mm. For matching

the normal panel and tile’s thickness,we have to add other material as the base for making the same thickness.But

different backing material have different features. So how to choose the right backing material confused many clients.

Till now,there are 4 common backing material. They are Acrylic or PVC ,MGO board, MDF board and non-woven fabrics

+resin.

Those backing material features are following:

1.Acrylic or PVC board(not suggesting):

Advantage: light weight,finished shell panel thickness can get from 4-8mm;

Disadvantage: Can not make big sheet(should be less than 600*600mm),the shape will change after heating or other outside press.So we are not

suggesting very much;

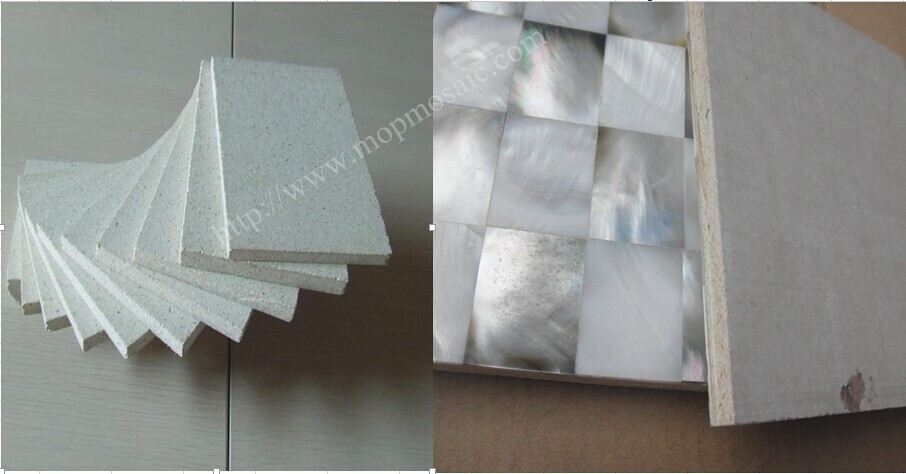

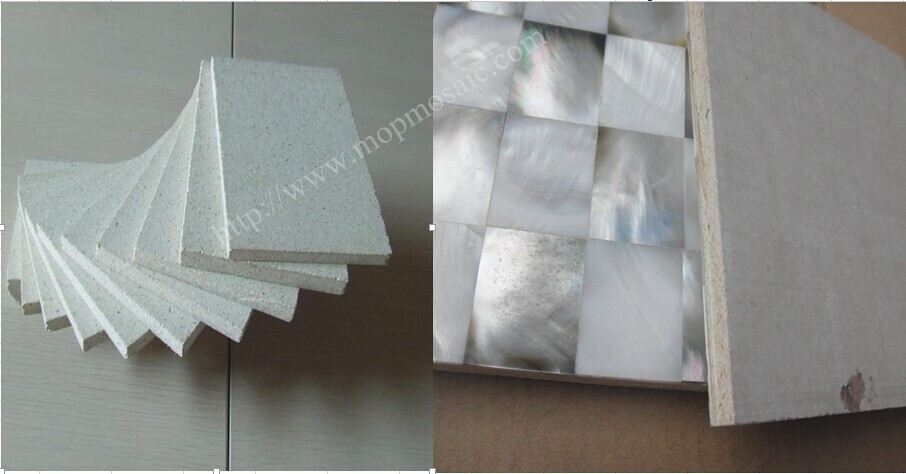

2.MGO board(Suggesting):

MGO board also called as glass magnesium board.They are very good solid backing material and this is the second

popular backing material in shell line.

Advantage: Can make big sheet and they are very stable.Can last the shape for a long time and install any place

which you want. The finished shell panel thickness is from 6-12mm;

Disadvantage: The weight is very heavy.It is not good for small order quantity client if they are shipping them

by express or by air;

For example: 1 square meter 8mm thickness shell panel’s net weight is 12kg; 10mm thickness shell panel’s net

weight is near 14KG;

3.MDF board(Suggesting):

Advantage:Can make big sheet and the sheet is very stable,finished weight is also in the middle;

For example: 1 square meter 8mm thickness shell panel’s net weight is 10kg; 10mm thickness shell panel’s net weight

is near 12kg;

Disadvantage:Can not use them near the wet area.The wooden backing material will be rotting after several years;

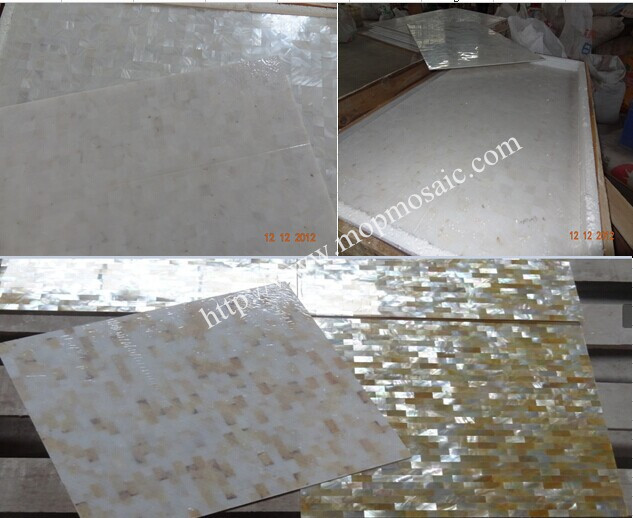

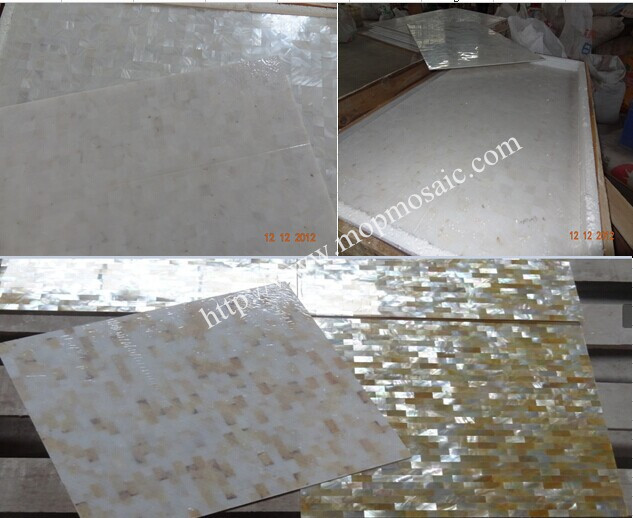

4.non-woven fabrics+resin(suggesting):

This is the most popular and most often used shell panel backing material in our company;

Advantage: Can make big sheet,light weight,less thickness,available for small order quantity;

The thinnest thickness is only 2.5mm; 1 square meter 4.5mm thickness shell panel’s net weight is only 5KG.Available

for small order quantity,totally save client’s shipping cost;

Disadvantage:we have to pack them very carefully for safety;

After reading those information,I guess you will have the idea about how to choose the right backing material now.We

suggest MGO board,MDF board and non-woven fabrics+resin as the backing material.

And our suggestion is following:

A.If your are importing from china very often, having your own container,any backing material is ok;

B.Big order quantity,have to shipped by ship-MDF board or MGO board;

C.Small order quantity and have to shipped by DHL or UPS or Fedex -Non-Woven fabrics+resin;

That will save your shipping cost a lot;

If you still don’t know which kind of backing material is suitable for you,please try to send an e-mail to us for suggestion. But before that,please make your address,our item number,chip size,sheet size and order

quantity in details.

Projects

Projects